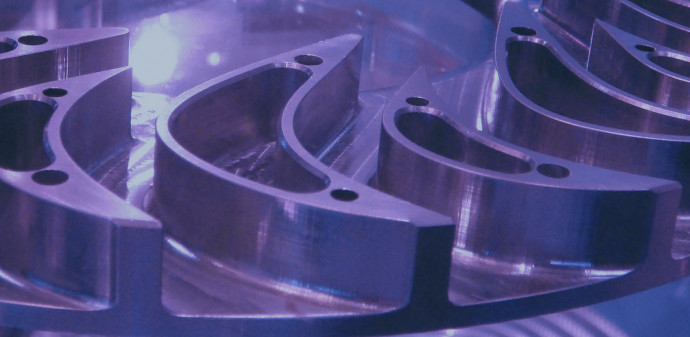

Our comprehensive plant capacity across two UK manufacturing facilities cater for both small & large component machining. Kenard’s offers extensive CNC machining capability, including: 5 axis machining, CNC turning, palletised machining, wire erosion machining, vertical turning, multi-axis milling, prismatic machining, fabrication, assembly, finishing, paint, coating and treatments. This enables us to offer a complete and flexible subcontract manufacturing service.

Tewkesbury Plant Capacity

Flexible CNC Manufacturing Centres

- 5x Mistsubushi M-H5B with 72 pallet Fastem linear rack system

- Mitsubishi M-H5B

- Mitsubishi M-H60E

- Matsuura M72-35V

- Doosan HP 5100

- Tsugami FMS 5 (x2)

- Hitachi Seiki 500

- Doosan DNM 650 (x2)

5 Axis Milling Centres

- Matsuura M72-35V

- Matsuura MX-520

Sheet Metal Equipment

- Promecam Press Brake

Inspection Equipment

- DEA Scirocco-nt Brown and Sharpe

- DEA Mistral Slout Bridge

- CE Johansson MIcro-Hite 3D

- Midland Metrology JT12 AZ Shadowgraph

Dartford Plant Capacity

Turn/Milling Machining Centres – including integrated 5 axis

- Mori Seiki SL603

- Mazak Integrex i400 Matrix 2

- Mori Seiki MT2500

- Hitachi Seiki HT40G

- Hitachi Seiki HT30G

Turning Centres, including Vertical Turning Centres

- Puma 700 LM (x3)

- Puma 600 (x2)

- Puma VCL VT900M

Flexible Machining Centres

- Doosan NHP 5000

- Mitsubishi M-H60E

- Mitsubishi M-H5B

Machining Centres

- Fadal VMC 4020

- Doosan Mynx 750 (x2)

- Mitsubishi FA30V

EDM Wire Erosion

- Mitsubishi FA30V

Inspection Equipment

- DEA Scirocco-nt Brown and Sharpe

- Mitutoyo 9166 CMM

- Baty SM350 Shadowgraph

- LK CMM G-90C

Cylindrical Grinding

- Jones and Shipman 1307 Cylindrical Grinder

- CEMB Balancing Machine EC011

- Studer S40 CNC Grinder