What we do

We always strive to deliver real value to our customers with a complete subcontract manufacturing service. Our dynamic and process driven approach, combined with a comprehensive range of multi-axis & 5 axis CNC machining facilities, gives us the capability and flexibility to handle highly complex operations. It allows us to support manufacturing programs, across multiple industry sectors, that fully comply with global quality standards.

- Multi-axis & 5 axis CNC machining

- 72 pallet flexible manufacturing system

- Prismatic machining

- Precision fabrication

- Waterjet cutting

- EDM wire erosion

- Grinding

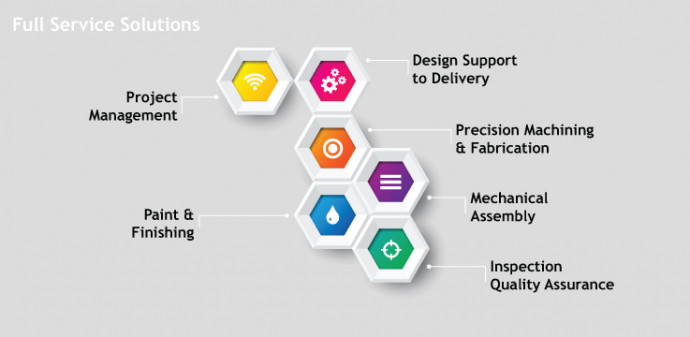

Design Support to Delivery

We support customers from the product development stage, where we are able to offer assistance and advice about optimised production techniques and costs to designers, through to full production, final test and assembly.

Services include:

- Design support

- Project management

- Production

- Mechanical assembly

- Sheet metal/fabrication

- Finishings, coatings and treatments

- Quality assurance and inspection

- Delivery

Delivering Value

Investment in the latest manufacturing technologies, production practices and processes ensures that our solution offering remains at the highest possible standard, both technically and in overall performance. We have always remained consistent in our approach, which is to deliver real value to our customers. Our reputation for quality, value and customer satisfaction is sustained by the high standard of products and service levels that we maintain.

Subcontract Manufacturing

With speed to market and greater responsiveness driving the change towards shorter, less complex supply chains, Kenard delivers a single source solution that encompasses a wide range of value adding services. This enables us to more effectively streamline our processes and workflows to meet your deadlines and budgets.

We offer an integrated, optimised approach to your subcontract manufacturing requirements, supported by supply chain and project management services. Our precision engineering capabilities include a wide range of machining processes, engineering support, component assembly, finishing processes and testing.

- Mechanical assembly and sub-assembly

- Paint and coatings

- Ultrasonic cleaning

- Chemical etch deburr

- Bead blasting

- Alocrom

- Phosphating

Project Management

Customer service is our main priority and our primary objective is to deliver your products on time, to budget and to a standard that exceeds your expectations. Experienced project managers will see your project through from start to finish. As your main point of contact they will communicate with you regularly to ensure that all parties are fully informed of progress and that any problems are highlighted early to avoid any delays to delivery.

Managing your project in this way will ensure that all information is centralised and that a number of complex elements are co-ordinated more efficiently. Our project managers will help to:

- Keep your project within the planned schedule and to budget

- Ensure compliance with all applicable requirements

- Monitor project progress and performance

- Record, manage and resolve issues

- Provide progress updates as required

We operate knowledge driven operations that are supported by real time manufacturing execution and production control systems. They provide live visibility of production progress, enabling us to provide you with realistic and accurate information about your project.