3D Printing Investment

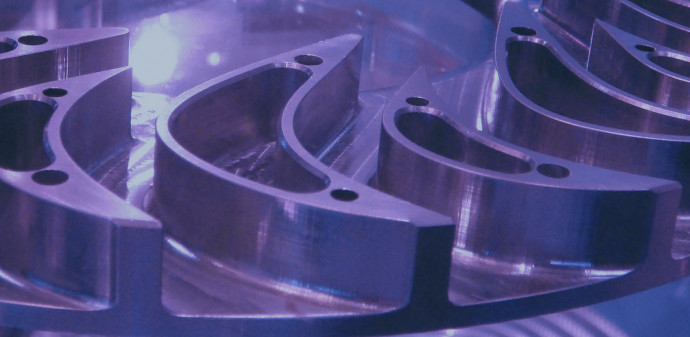

Our Dartford facility recently invested in a desktop 3D printer after recognising the benefit of using the technology to produce concept models to support the estimating and quoting processes. We are now able to print models of parts to get a real object to analyse and determine how to design the part for manufacture. This is a huge step on from sitting and studying a drawing.

There’s another highly practical application for this technology. Masking up a part with tape ready for spraying or coating is an extremely time consuming and not a particularly reliable method as the tape will peel off or frequently cause bleeding under the edges. 3D printed masks allow us to create very precisely fitted covers that completely protect the covered areas. Both Tewkesbury and Dartford are currently using this method, to produce a higher quality finish.

Related links:

#3dprinting