Strong Growth Drives Further Investment

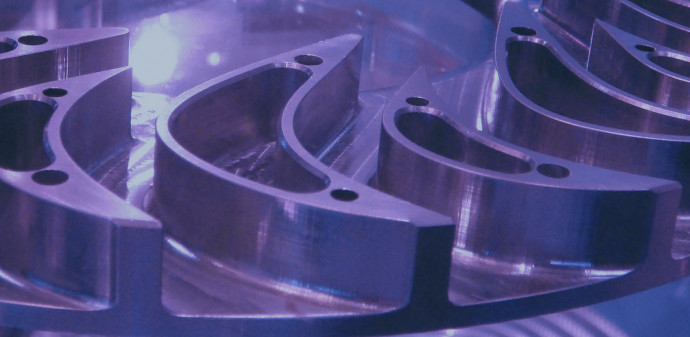

Eight months into its current financial year, sales revenue at Dartford was almost 20% ahead of target. This has led to a strategic machining technology investment with the purchase of a new Puma 700 turning centre at our Tewkesbury facility.

Not only does this investment provide the increased capacity needed to meet the Group’s existing and projected demand, it also facilitates the further development of the group’s turning capabilities, widening its prospective customer base for the future.

The strong sustained growth has driven a number of initiatives at Dartford to help maximise production and sales efficiency. These have involved the entire workforce and already generated reduced cycle times, material cost savings and better machine utilisation. At the heart of the improvements has been increased use of the company’s production management systems and processes to share information on a business-wide basis, more accurately and quicker than ever before.

Specific continuous improvement initiative examples include the use of two visual management boards that provide an overview of performance, health and safety and improvement process information as well as staff handover notes. The boards also house LCD screens that include a seamless wireless link to Kenard’s live production information allowing sales and production teams to review real-time Key Performance Indicator (KPI) data. Providing a critical visual management focal point, these boards have transformed the function and effectiveness of the company’s daily production management meeting.

Weekly senior management meetings that monitor progress against projected targets have also been transformed. Previously the job of collating the requires sales and production data took the Dartford Operations Director and General Manager a couple of days each week. Even then, despite their considerable experience, the data was not as accurate as required to provide not just a forecast of planned throughput but also highlight the real reasons for delays in production or areas that require additional investment. Now this information is automatically derived from the company’s Seiki Advanced Planning and Scheduling (APS) tool and shop floor data collection system which in turn has been made possible by significant improvements to internal processes. The result has been improvements in a number of areas including stock control, capacity management and on-time deliveries. This increased visibility and improved accuracy of critical production data provided Kenard with a sound business case to invest in the new Puma 700 turning centre.

Keith Ellis, Managing Director of the Kenard Engineering Group, comments on the achievement:

“Next year we celebrate our 50th anniversary which is a terrific achievement for any privately owned organisation, especially in these challenging times. We can’t control the factors that influence the business and economic environment but what we can do, and have successfully done over the years, is ensuring that we are as responsive as possible as a company. This means investing in the best people, processes, equipment and IT solutions and then working hard to get the very best from each. This in turn means we can then give the very best to our customers in the present, and confidently on into the future.”