New Business Development Manager at Tewkesbury

We are expanding our customer sales and support operations with the appointment of Dave Varney as business development manager, bringing a wealth of experience gained in a number of high technology industry sectors.

With a brief to promote the Group’s capabilities to both existing and new companies Dave Varney has been appointed business development manager for the Kenard Engineering Group, bringing over 30 years experience in the manufacturing sector, including all aspects of precision machining in the defence and rail sectors. As he explains: “Within the new job role I have a wide and varied remit, which includes planning, estimating and customer focus, for which my knowledge of manufacturing engineering and processes will provide an invaluable understanding of customer requirements and expectations.”

As a time served engineer, Dave Varney started his career as an MoD apprentice at Royal Ordnance Nottingham, which later became part of BAE Systems. He was there for over 30 years working on the company’s various machine tools before taking promotion onto the artillery section, which produced barrels for tanks as well as field guns. Another aspect was taking the responsibility for setting up an aircraft cannon line which was relocated from a London facility, before moving over to the precision based cellular manufacturing section.

Following this wide and varied experience in the defence industry, Dave Varney gained an exceptional insight into the rail infrastructure industry. Working for world-class engineering and construction specialist Balfour Beatty he was involved with the manufacture of railway piece parts and high speed crossings. A change of direction followed after two and a half years, moving to a local engineering company in Nottingham, and was involved with estimating, planning and manufacturing engineering for the precision engineering company’s wide base of customers in various industry sectors, such as nuclear, aerospace, petrochemical, electronics and automotive research.

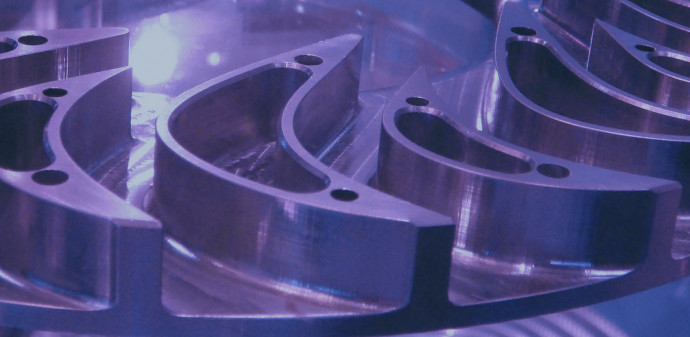

The Kenard Group specialises in manufacturing precision components using modern manufacturing methods. Operating from two UK sites, the Group offers a complete manufacturing service, including design for manufacture, project management, precision machining and fabrication, sheet metal/welding, mechanical assembly and electro mechanical assembly. Dave Varney maintains that Kenard has always enjoyed a reputation for their customer focus, which he explains is due to the value adding capabilities of the company, “Customer service is a of high importance to Kenard, we aim to work with all our customers from a concept-design stage to full manufacture, including all processes and treatments and project managers frequently holding activity meetings with customers in order to ensure that the best results are achieved, notably concession free products at the right cost and on time delivery.

He continues, “The main strengths of the company reside in the flexibility provided by operating two manufacturing sites and the breadth of skills and knowledge held within the Group. ” Kenard have 32 CNC machine tools between both sites, with a maximum turning capacity of 930mm diameter to a length of 3000mm, and also both vertical and horizontal multi pallet machining centres. The Group manufactures 1 off prototype components through to medium batch (200 off) production requirements. Kenard Engineering’s Tewksbury site predominantly machines aluminium at high speeds on horizontal, vertical and multi pallet machining centres, most notably a 72 Pallet Fastems system. Producing parts for civil and defence aerospace customers the complexity of the components and stringent precision quality procedures provides a constant challenge. A modern purpose built factory at Dartford specialises in turning with the latest technology Mill/turning machines and the use of exotic materials.

Operating within the very latest quality systems expected by the aerospace industry, including AS/EN9100, Kenard will be looking to extend further into this sector which demands high specification, high quality, and high performance components. Says Dave Varney: “Outside the aerospace industry, we also supply control and instrumentation kits, oil and gas parts, and components for road haulage and transport such as chassis and covers, which house electronic instrumentation. I will, of course, be extending our services further into the Defence, Oil and Gas and automotive sectors. There is capacity within the workshop to meet growth and the company is willing to invest in technology to provide the level of service our existing customers have become accustomed to. In fact, we are currently looking at waterjet technology to further differentiate Kenard from its competitors by increasing our capabilities and enhancing our ability to offer a complete manufacturing solution.”