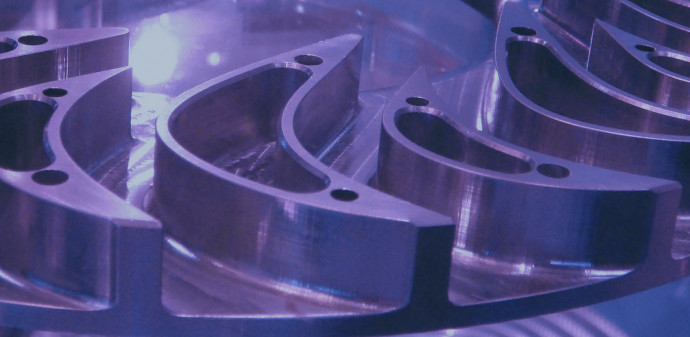

New 5 Axis CNC Machining Centre

Kenard Engineering Tewkesbury has taken delivery of a new Matsuura MAM72-35V 5 axis CNC machining centre. This £550,000 investment demonstrates our ongoing commitment to invest in new and advanced technologies.

Designed for long periods of unmanned 5 axis simultaneous productivity, the Matsuura MAM72-35V has been a market leader in its class for more than 20 years.

This investment is designed to improve our “lights out machining” capability, increase the accuracy of machined components due to a fewer number of operations and radically reduce the manufacturing time of complex components.

Technical Specifications

- The machine is fitted with a 15,000 rpm spindle, which is ideal for aluminium components.

- It has a 320 tool magazine to allow for a large number of jobs to be continually set.

- A 32 pallet automatic workpiece loading system

- An advanced tool management system that loos at the machining schedule and forecasts the tooling requirement for the schedule to be completed.

Following a successful installation, the first component is now nearing completion and the initial signs are that the anticipated productivity improvements are going to be realised. The number of operations on the first component has reduced from 7 to 2 and the machining cycle time reduced from 4.5 hours to just under 2.

Watch the official Matsuura demonstration video.