Intake of Machining Contracts Rises 30% at Dartford

Following a re-organisation of our production scheduling and the installation of over £1 million of ‘one-hit’ machining technology equipment, contracts for producing high value components for the oil and gas, aerospace, medical, telecoms and motorsport sectors have risen by 30% in the first six months of this year.

Managing director Keith Ellis explains: ‘Customers are demanding ever shorter lead times and if you are able to respond and guarantee quality, there is still significant high added value work available in the UK.

In general we have been able to reduce our delivery lead times from between 12 to 16 weeks, which was typical of five years ago, to under four weeks now and we are well on track to hit our 40 day target from enquiry to delivery.

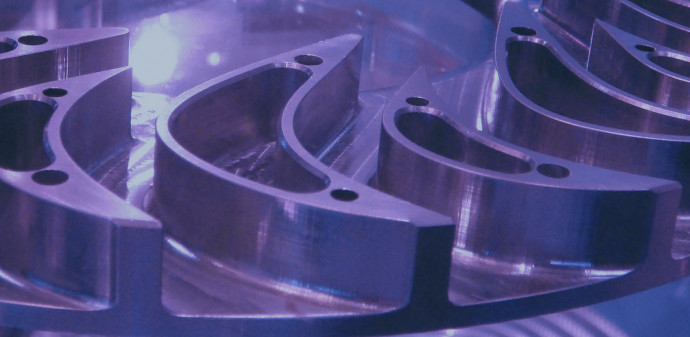

Most of the work at the Dartford site, which employs 55 people, is high in precision and value and is produced on 15 CNC lathes and machining centres. Currently the most expensive component on the shopfloor is an aerospace bearing worth more than £6,500 each. These bearings are produced in batches of 10 involving almost 40 different processes.’

Recent investment of over £1million has included a Mori Seiki SL603 mill/turn centre which enabled the company to almost double the size of its machining capacity from 500mm to 1000mm diameter and accommodate parts up to 2000mm long and a Mori Seiki MT2500 simultaneous five-axis mill/turn centre with 120 tool capacity. But, maintains Ellis, the key to achieving these high production targets has been the installation of Seiki Systems totally integrated manufacturing execution systems (iMES) giving ‘real-time’ feed back with live dynamic predictions of machine workloads such as projected completion dates and performance reporting in a paperless environment.

The iMES system provides planning, a real time scheduler, display of all stages of relevant manufacturing data right through to final dispatch and management reporting. Says Ellis: ‘At any time we can have upwards of 320 jobs on the schedule which can easily comprise 3,000 separate operations.’ But here, the investment in ‘one-hit’ machining technology has enabled Kenard to combine five or six operations into one or two cycles. ‘That has made a real difference – we know it is paying off by the order book,’ he maintains.