Contract Machining Sales Rise 20% at Tewkesbury

With sales set to rise by at least 20% at Tewkesbury, managing director Keith Ellis maintains the business is looking forward to 2006 with the highest level of confidence in almost a decade. He confirms contract machining services sales rose by £100,000 a month through 2005 against three years ago and topped out in November with billings in excess of £400,000 from completed deliveries to the mining, telecoms, communications, rail, aerospace, oil & gas and motorsport sectors.

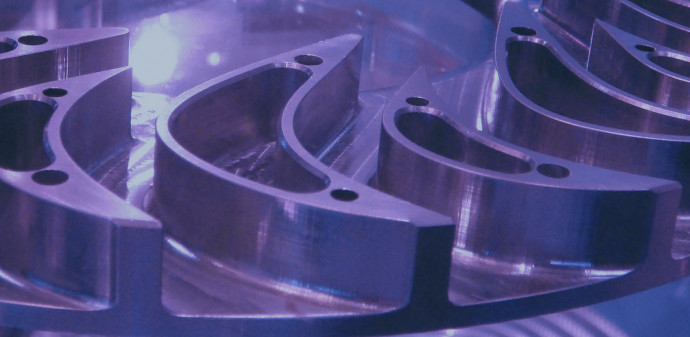

This is confirmed when looking around the shop floor of the 47,000 sq ft facility. A line of five, four-axis Mitsubishi MH500 horizontal machining centres configured into a flexible machining system (FMS), with a Fastems 72 pallet magazine, is running largely unmanned through 24 hours a day and often over weekends. The sheet metal area with punch press, press brakes, guillotines, and welding bays is busy, whilst large horizontal and vertical machining centres are ideally loaded with a wide variety of small and medium batch work.

Operational strategy & ownership

The dedicated plastics machining facility and a composite machining cell both have good forward order books and prototype, sub and final assembly areas hives of activity. Keith Ellis adds, “The whole plant is run by two people; Roger Aplin as commercial manager and Garry Dring as production manager. They have instilled a very simple ‘Ownership’ philosophy throughout the workforce team of 50 people and it’s working well.” Recent changes to the operational strategy have even led to the turning away of low profitability contracts. Focusing on core operation has not led to a loss of business as the company has found that by concentrating on higher added value we are drawing more high quality work from key customers, becoming a preferred supplier. From discussions with these key customers Kenard has found the trend is definitely to reduce the number of suppliers and the focus is shifting to use a larger contractor that can provide the complete service as a package. ‘We have definitely benefited from this change of thinking,” says Ellis.

Production control and manufacturing execution

Early in 2005 the Kenard Engineering headquarters at Dartford brought its Seiki Systems iMES manufacturing and production scheduling system on line to control day-to-day events on the shopfloor. Almost immediately it helped to improve production efficiency, reduced lead time and improved deliveries. By mid-year, the Tewkesbury site was integrated with live links back to Dartford to provide a totally transparent capacity, work-in-progress, production analysis and management reporting system right across the site covering the 18 CNC machines, as well as benchmarking, painting, sheetmetal production and assembly. While this has provided information in ‘real-time’, the spin-off has been a new level of confidence across the business. Says Ellis: ‘We are now very proactive, which is an important addition to the ownership philosophy and we can predict from the computer screen, for instance, our turnover for a month, look at job queues and shuffle work flow to shorten lead times.

It is easy now to slot new work in or more importantly, provide very early warnings to customers that there could be a problem and create an action plan.’ He follows on with an example where contractors are required to use ‘free issue’ material from the customer but delivery, which is out of the contractors control, is running late. ‘We can now give the customer precise information on the consequences or let him know how we can reschedule to accommodate the situation so he does not need to waste time by passing panic down the line of supply,’ Ellis says and follows on: ‘This has had a tremendous impact on customers, since they realise, and then understand, that we are talking about factual information.’ Kenard’s business success has also been helped through its heavy investment over the last couple of years in installing some £3 million of equipment at Tewkesbury and £1 million in Dartford. This was driven by the desire to improve production through the use of automation when it was economically viable. ‘Now with growing order books we need a few more people,’ says Ellis, ‘But to qualify they have to have machining knowledge and be able to appreciate what ‘ownership’ is all about. Also ‘on the cards’ for 2006 are two apprenticeships, seen as the start of a long term training programme for the key people for the future.