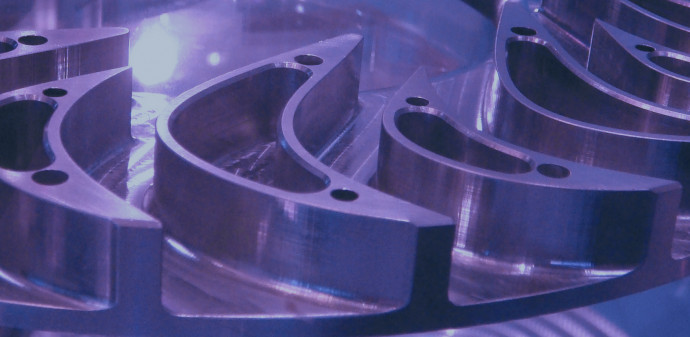

Advanced Manufacturing

Our thorough and analytical approach to the entire manufacturing process ensures that the integrity of your original design is maintained and products of the highest quality are delivered when you require them.

The skills and knowledge that the Kenard team has acquired and nurtured is based on significant experience within a wide range of industries. The Tewkesbury facility has grown and evolved over the years to incorporate specialist precision machining capabilities that enable us to work to extremely close tolerances in a wide range of exotic materials. We have also extended our capabilities to include a wide range of value adding services to provide our customers with a single-source solution.

Manufacturing capability and in-house facilities

- Precision multi-axis machining

- Prismatic machining

- Sheet metal / fabrication

- Powder coat and wet spray

- Ultrasonic cleaning, chemical etch deburr, bead blasting, alocrom and Iridite NCP treatments

- Quality inspection

- Comprehensive in-house test facilities

- KPI performance analysis

- On Time In Full (OTIF), Ship to line, Kanban