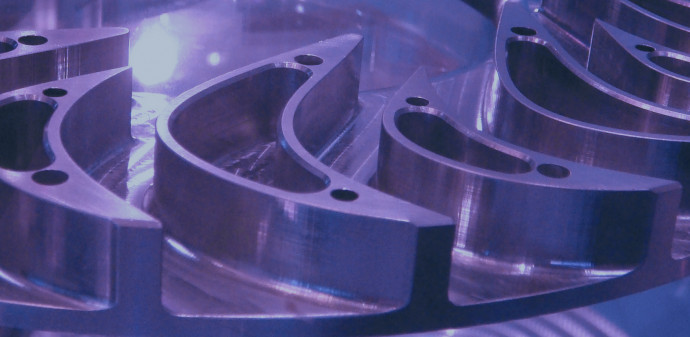

New Mach 3 131B Waterjet machine installed

The latest investment phase of our ongoing manufacturing growth strategy is now complete with the installation of the Mach 3 131B waterjet cutting machine and fast response cell at our Tewkesbury facility. This strengthens and expands the company’s existing capabilities.

Investment that benefits customers

Kenard’s investment in the Mach 3 131B Waterjet was made on the basis that it offered significant setup and machining time improvements providing a range of benefits that could be then passed on to the customer. Central to this is a lower component manufacturing cost, resulting from a more efficient process requiring fewer operations and a reduced machining time – in some cases, the number of processes have been reduced by a third.

The greatest advantage however has come with the ability to profile pure copper components with a minimum of waste, as other methods such as wire eroding, laser cutting and plasma cutting etc. are not suitable because of the heat induced recast layer generated on the cut surface. Water jet cutting is also extremely flexible and can be used to make thousands of identical parts for high volume manufacturing right down to one-off, bespoke parts. It can even be used to modify existing parts without the need for expensive re-tooling or setups, saving time and money and providing ultimate flexibility for the customer.

Keith Ellis, Managing Director of the Kenard Engineering Group, comments on the investment: “We continue to be extremely optimistic about the economic climate for manufacturing in the UK, with good levels of enquiries and new business opportunities. Our main focus is therefore on increasing our capabilities becoming as efficient as possible in order to remain competitive and offer our customers a complete, value added service.”