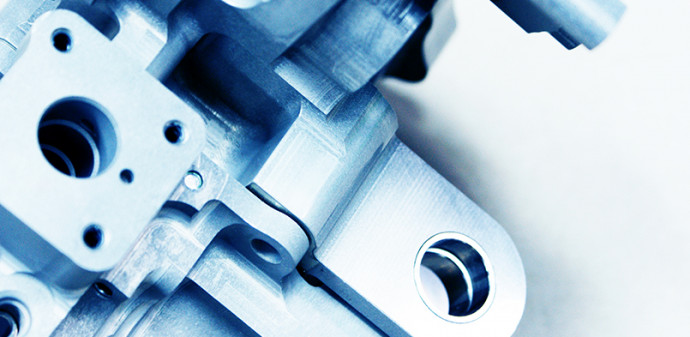

Precision Machining

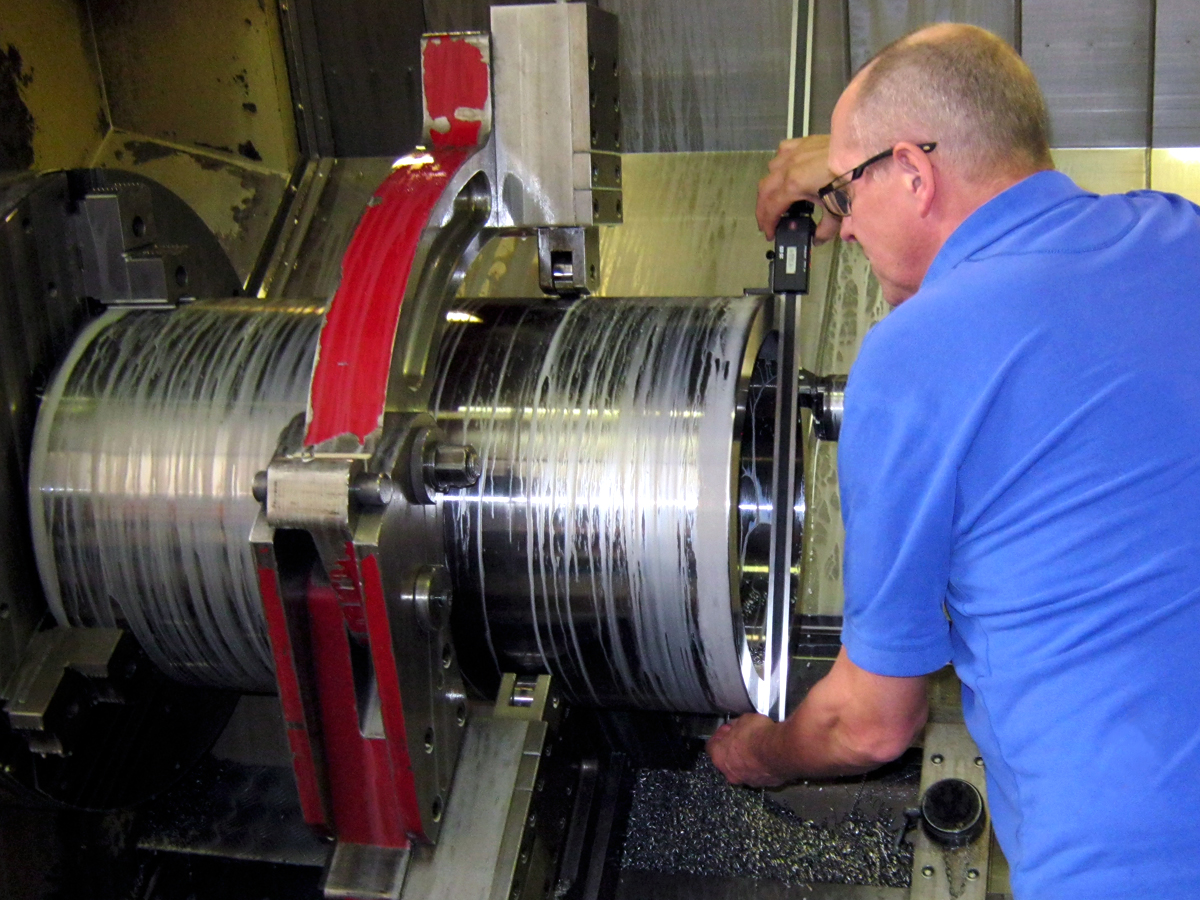

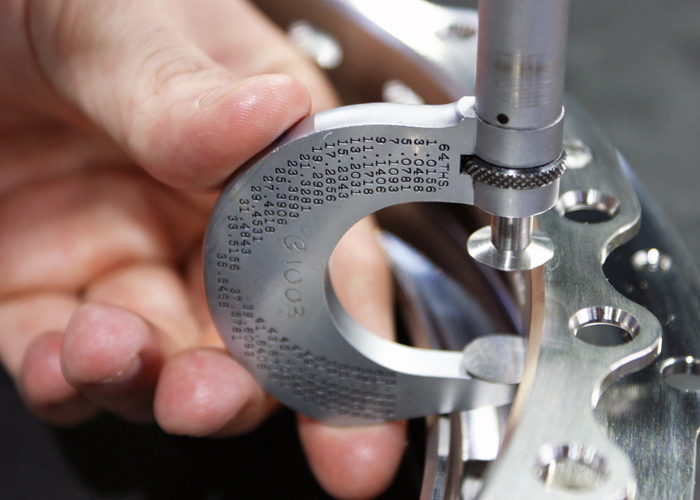

Kenard Dartford has a fully equipped machine shop that is supported by the latest CAD/CAM software. Our capacity includes multi-axis, vertical and horizontal milling and turning CNC and manual machining, with a maximum turning capacity of 930mm diameter to a length of 3200mm. Comprehensive CMM inspection facilities ensure the accuracy of all components that we produce to extremely high tolerances. View our Machining Capability Matrix.

EDM Wire Erosion

EDM Wire Erosion enables us to work with exotic materials, hardened metals and exceptionally ductile or brittle materials that are difficult to machine. The benefits of EDM Wire Erosion include:

- Excellent surface finish

- Burr free finish

- Supports the production of highly complex, contoured shapes from a single work piece

- Repeatable tight tolerances results in consistently high quality finished products

- Multiple products can be cut at once, optimising the efficiency of the resources and reducing lead times

Materials

We are able to work with a wide range of materials, including Iconel, Super Duplex, Hastelloy, Aluminium Alloy, High Tensile Steels, Stainless Steel and Copper Alloys.

Access our complete plant list