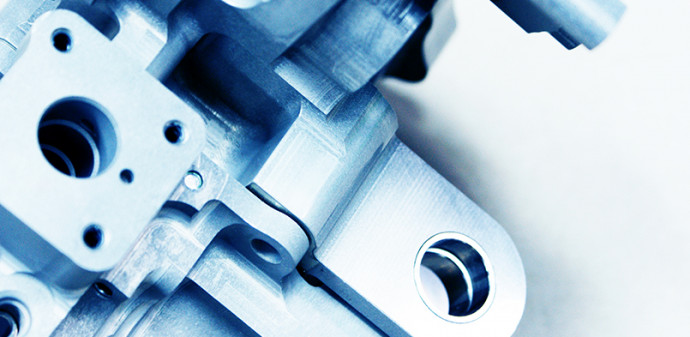

Continuous Improvement

Globalisation and new technology innovations are driving an ever evolving business environment. To ensure that we are responsive to changes in industry and continue to meet customer demands a philosophy of continuous improvement underpins all our activities.

Formalised best practices such as 5S, Lean, Visual Management are used to identify opportunities for maximising the utilisation of our production resources – people, skills and machinery. These operational methodologies enable us to streamline the manufacturing environment, increase efficiency and to eliminate waste.

Information Rich

As the company has grown we’ve implemented manufacturing systems to manage the flow of manufacturing data and business information both locally and throughout the Group. Integrated ERP, CRM, APS (Advanced Planning and Scheduling), shop floor data collection, resource monitoring and performance analysis software systems ensure that we operate in an information rich business environment.

Manufacturing Performance Management

The ongoing process of analysis and review ensures that we are able to take a knowledge driven approach to our continuous improvement strategy, resulting in benefits for our customers that include:

- Faster response to their requirements

- Improved order cycle times

- Improved quality of output